Contact Info

Resources

Uni Cryo 660

Hydraulic Fracturing Hose ( Fracking ) Speacial Aramex Outer Cover For Minimal Abrasion.

Applications

More commonly known as fracking (fracing), hydraulic fracturing is the process in which fractures or fissures are created within shale formations that allows trapped natural gas to flow and be recovered.

Sand, water and other additives are transferred from pumps into the formations of the rock to create fractures and Universeflex Frack Hose is the safe handling hose to lead the way. Universeflex Frack Hose are highly flexible which is effective and efficient for maneovrability in connecting even when temperatures are sub zero.

Light weight and highly flexible at both, very low or very high temperatures outside , make for great hose maneuverability in connecting and disconnecting all day long.

Universeflex Frack Hose composite hose assemblies are the highest available quality and the ideal hose to support the transfer equipment for fracking. The Matec Group has extensive experience in supplying these hoses into the fracking industry.

Universeflex Frack Hose hose assemblies have a custom swaged/crimped end fittings for easy and quick connection to the equipment and is a proven safe transfer with reliability. Flanged ends, BSPT or NPT, Hammer Unions, or Victaulic are available.

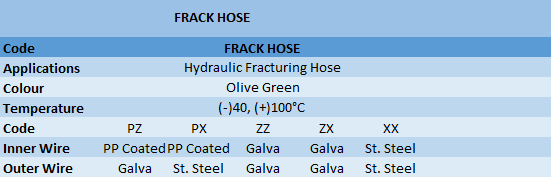

Construction

This is a robust polypropylene lined chemical transfer composite hose which is available with polypropylene coated, stainless steel or galvanized steel wires, from 1″ to 12″ diameters. Extra reinforcement, UHMW PE and Polyester film barrier layers. Extra strong / low elongation Aramex special outer cover is used for superior resistance to the abrasion, weather and ozone.

Specifications

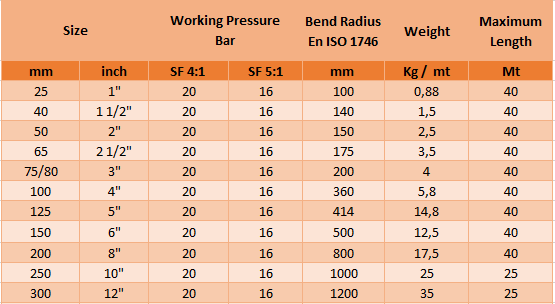

Temperature range from – 40°C to + 100°C W.P. 16 Bar – Safety factor 5:1

Universeflex Frack Hose assemblies are tested at 1 ½ times rated working pressures for safety and reliability, in accordance with EN ISO. The securing ferrule, at one end of the hose, is permanently marked by embossing, with manufacturer’s name, nominal bore, serial number and the test date.

Burst pressure indicated, is at ambient temperature when tested in accordance with EN ISO 1402.

Electrical continuity is achieved by the two wires bonded to the end fittings, this helps dissipate accumulated charge and to avoid static flash. Upon request it’s possible to manufacture Universeflex Frack Hoses in accordance to the Directive 94/9/EC “Atex”, with a special outer antistatic black cover and cable for ground connection.

Assemblies are suitable for use with a vacuum not exceeding 0.9 Bar.

Universeflex Frack Hoses can be supplied in the Firetec version to meet the Fire retardand performance criteria acc. to European Standards EN 13765 Normative, Annex G, and with ADR self-estinguish CL1 characteristics.

Firetec hose utilize a series of fire retardant barriers and an outer cover made of special ADR self extinguish CL 1 coated fabric. All Universeflex hoses meets the EN, CE, AS, U.S. Coast Guard requirements, NAHAD Guidelines, are Lloyd’s and DNV approved.