Contact Info

Resources

Uni Bio 85

Universeflex Bio is a multy-layer thermoplastic Firesafe hose, manufactured from several Polypropylene, Polyethylene, Polyester films, reinforced with high tensile fabrics, and an external Class 1 Fire retardand cover. First layer, in direct contact with conveyed product, is made in a special film, 100% resistant to aromatics and MTBE. Universeflex Biotec, includes in its construction an UHMW PLT Seamless tube film, to avoid any possible leak and guarantee a gas-tight construction.

Application:

Universeflex Bio hose, is a Biofuel suction and discharge hose, particularly suitable for such applications due to its excellent chemical resistance and its relative lightweight and flexibility. A hose designed for suction & discharge of products at temperatures from – 40 to +100°C

Universeflex Bio hoses indicates products which have compatible chemical resistance with all types of new alternative fuels, such as:

Bioethanol (up to E98)

Biodiesel* (up to B100)

And traditional petroleum-based fuels:

Gasoline

Diesel

*Applies to biodiesels which meet ASTM D6751 criteria

Bio 85 is a special fuel hose, designed to handle all grades of Ethanol fuel blends. Biotec 85 hose is built with a specialized combination of high performance films and fabrics designed to handle today’s fully concentrated alternative fuels. Bioethanol is readily made from the starch or sugar in crops such as corn, wheat, beet and sugarcane. Bioethanol is a clear, colourless, flammable, oxygenated hydrocarbon which can be used as a transport fuel. This can be blended at any level with gasoline to create a biofuel blend.

Bio 100, is an alternative fuel hose, designed to handle all grades of Biodiesel including 100% neat biodiesel . Bio 100 hose is built with a specialized combination of high performance films and fabrics designed to handle today’s fully concentrated alternative fuels. Biodiesel or FAME (Fatty Acid Methyl Ester) is produced from different sources like soft oils (i.e. rape seed and soy bean oil, etc) and tropical oils (palm and coconut oil, etc.); this can be blended at different percentages with petroleum diesel to create a biodiesel blend.

This product can reduce air pollutant emissions in particular the lack of sulfur allows the gradual elimination of this substance as the main cause of the formation of acid rain. Another important aspect from the ecological point of view is the amount of carbon dioxide that the Biodiesel releases during combustion, which is exactly that absorbed by the plants during their growth, this offers the possibility of avoiding the accumulation of carbon dioxide, because of “greenhouse” effect.

Non-permeable construction – won’t swell or become stiff like conventional thermoplastic/rubber hoses. Long life reduces operating costs.

Lightweight – much lighter than conventional Thermoplastic/rubber hoses.

Superior flexibility – especially in sub-zero weather.

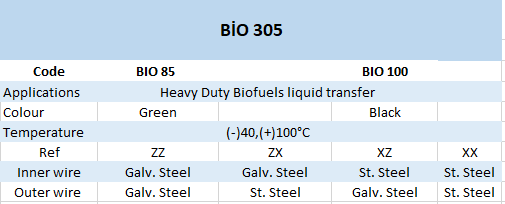

Electrical continuity – Electrical continuity is achieved by the two wires bonded to the end fittings, this helps dissipate accumulated charge and to avoid static flash. Upon request it’s possible to manufacture Biotec hoses in accordance to the Directive 94/9/EC “Atex”, with a special outer antistatic black cover and cable for ground connection.

All Universeflex hoses are 100% Antistatic – Electrically continuous, meets the EN, CE, AS, U.S. Coast Guard requirements, NAHAD Guidelines, are Lloyds and DNV approved and ATEX certificate can be released on request.